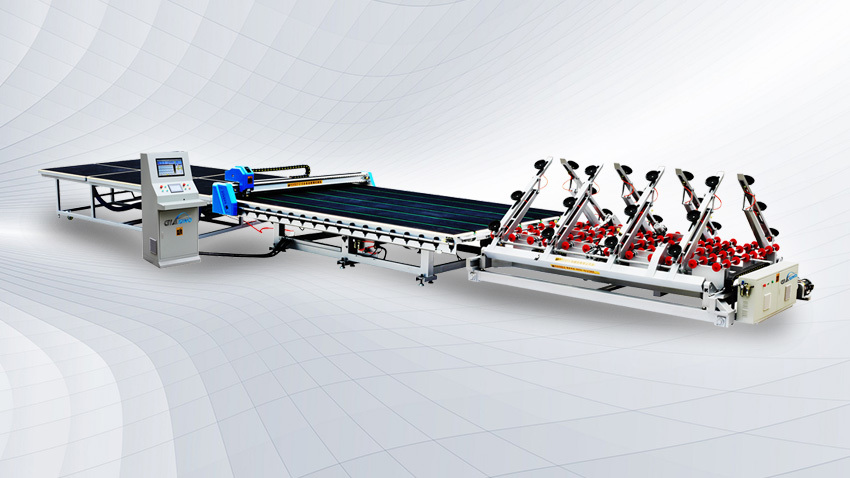

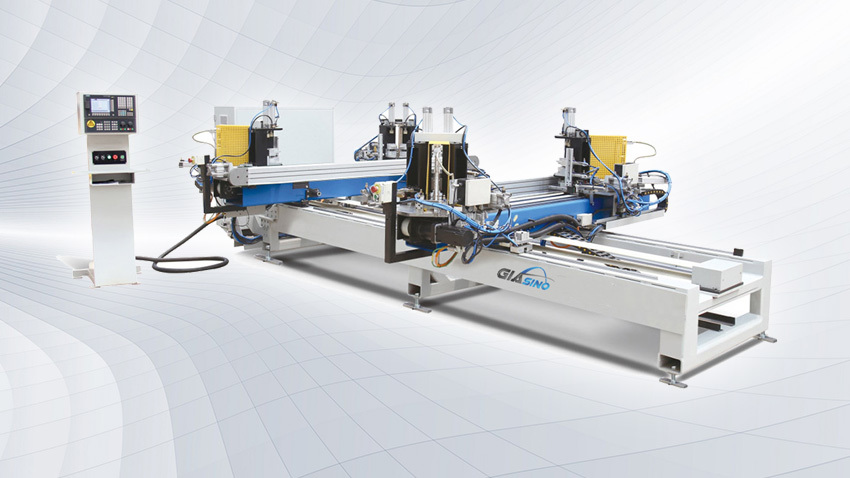

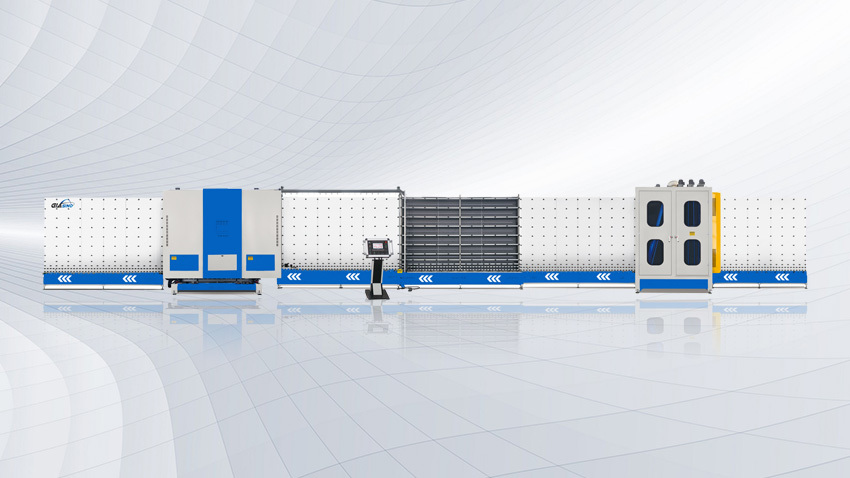

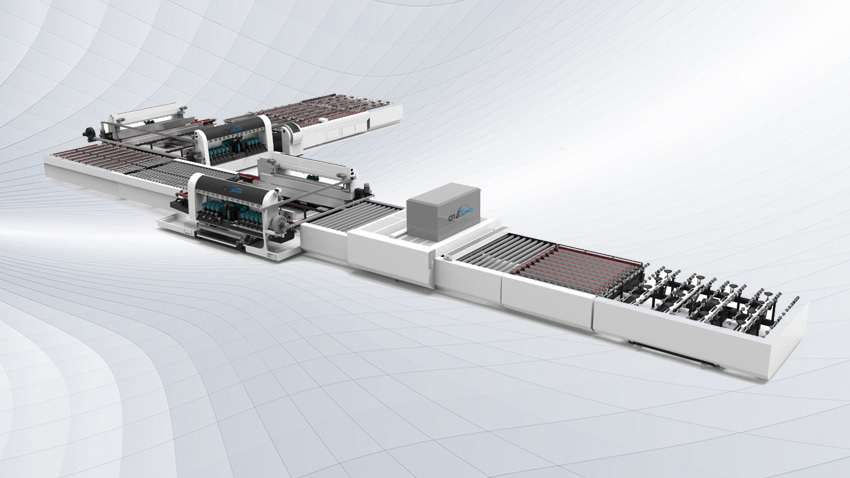

PRODUCTS SHOW

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp:

+86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

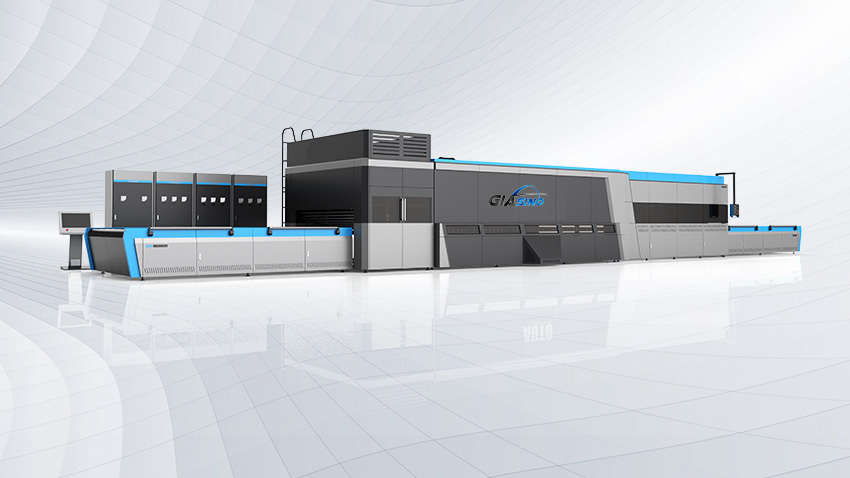

LXWG1208A Continuous Bend Glass Tempering Machine

Category:

Summary:

Tel:

E-mail:

DESCRIPTION

1.Machine Application

LXWG1208A bend Glass Tempering Machine is a special plant used to produce the bend tempered glass,which mainly used in the fields of side doors(sidelites)of automotives,trucks,shower room,furniture,etc.The side door of the automotive is single curvature and can be double curve and machine is continuous type.Our customer produced the side doors for Audi,Toyota,Honda,Hyundai,Peugeot,etc.

2.Supply Scope:

2.1.Loading/unloading table

2.2 glass cooling&forming section

2.3.Heating section(it is designed to double-chamber construction inside of heating oven)

2.4.bend tempering&forming section

2.5.Unloading table

2.6.Blower system(blower installed at side of machine)

2.7.Electrical&control system

2.8.Emergency power system(EPS)for emergency driving system

2.9.Emergency cooling system

2.10.Spare parts as listed in appendix

2.11.Technical documents

2.12 LED display

2.13 Pressing rollers accessories will be supplied,for fast and convenient replacement.

2.14 ceramic washers will be used together with stainless washer for fixing heat-insulating material in the heating oven.

2.15 more thickness of insulating material used at front and back oven door side and top of Furnas about 330mm thickness.

2.15 Isolite brand material for part insulating.

3.Technical Specifications:

3.1.Basic parameters

bend Tempered Glass (Six working position) | |

Max. single bend Glass Size | ⌒650x1200 mm(Eight working position) ⌒800x1200 mm(Six working position) |

Max double curvature size | ⌒800x1100mm(Five working position) |

Min. Glass Size | ⌒280x200 mm |

Glass Thickness | single bend 3.2-5 mm |

Blower Quantity & Power | 355kw+55 kw (Controlled by frequency inverter) |

Minimum Radius | R≥1200mm for 3.2-5 mm |

Capacity | About 180-200 pcs per hour (3.2mm as sample) |

Roller Pitch Of Heating Section | 130+110+80mm (smaller pitch design) |

Roller Pitch Of Bending Section | 68mm (smaller pitch design) |

Quality Standard | EN12150-1:2000, ECE R43 or ANSIZ-97.1 |

Finished product rate | ≥96% (4mm as sample) |

3.2.Installation Power&Transformer Capacity

| (KW) | Remark |

Heating Power | 1000 kw |

|

Quenching Power | 355kw+55 kw |

|

Others | 18 kw |

|

Total | 1428kw | The actual running power is about 70-80% |

Transformer Capacity | ≥1000KVA |

|

3.3.Other requirements(Supplied by buyer)

Special Request |

| Remark |

Ground Flatness | +0/-20 mm | Concrete more than 200mm in thickness |

Air Compressor | 1.5 m3 / Min, 0.8MPa | The compressed air should be free of water & oil, and be sufficient in terms of airflow & air pressure |

Air Tank | 0.61 m3 |

|

Consumption | 0.3 m3 / Min |

|

Key words:

Product Message

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: