PRODUCTS SHOW

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp:

+86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

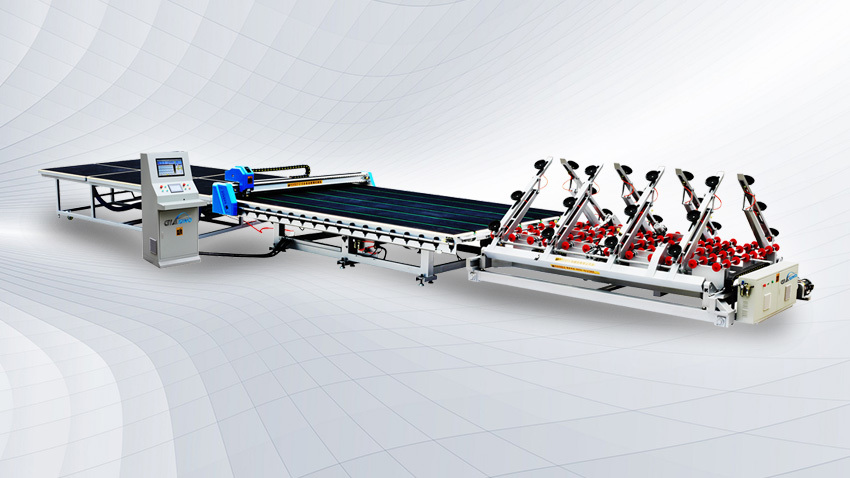

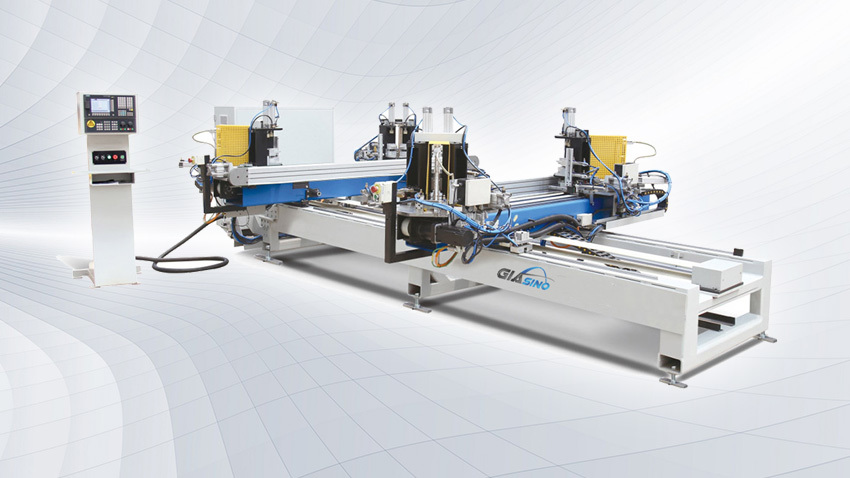

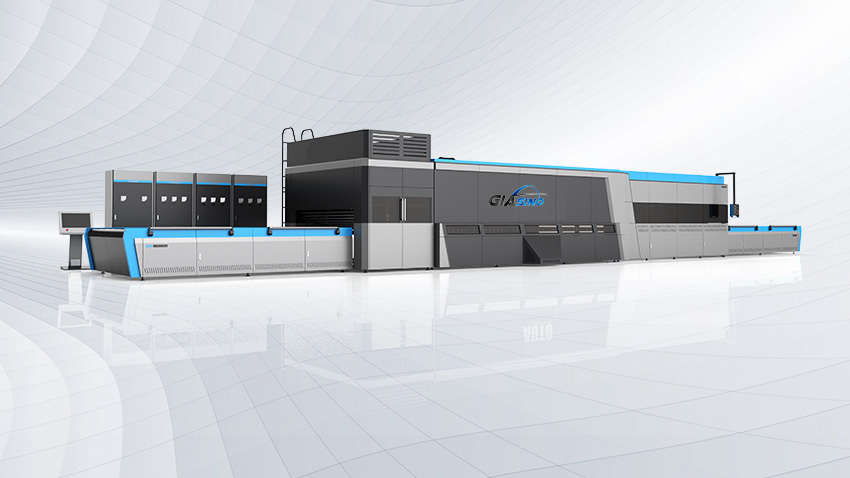

Fully Automatic Glass Cutting Machine Grooving Machine

Category:

Summary:

Tel:

E-mail:

DESCRIPTION

1.Equipment Specifications

Max. glass size | Height | Dimensions | Weight |

2500*900mm (manual assistance is required for more than this layout) | 900±50mm | 3500*1600*2000mm | 1700KG |

2. Grooving parameters

Principle axis positioning accuracy ≤±0.2 mm

Cutting bridge speed: 0~100m/min. (adjustable)

XY axis coordinated movement speed ≥ 100 m/min

The speed of the cutting head holder ≥ 100m/min

The cutting head holder acceleration ≥ 3.5 m/s²

Grooving accuracy: ≤±0.20mm

3. Power Supply/Power

Installation power requirements: 380V/50HZ

Equipment installation power: 16KW

Compressed air: 0.6MPA

4.Equipment performance

Equipment frame:

The equipment has undergone professional structural software analysis to ensure the stability, dynamic balance, and mechanical strength of the machine to achieve the most perfect fit, to ensure that the table is not deformed, and the parallelism is accurate.

Principle axis system: 360 degree rotation of the grinding head (grooving according to various graphics)

Tabletop: using polymer nylon panel, overall milling.

Positioning device: mechanical positioning

5. Mechanical part

Platen | Polymer nylon (flatness≤± 0.10mm/m) |

Rack | Taiwan K.H |

Rail | Taiwan Hiwin |

Grooving tools | Independent research and development of high-performance drilling and grinding tools |

6.Electrical part

Directly controlled by brand computers, Microsoft Windows interface | |

Voltage | 380V/50HZ |

Motor | Inovance servo motor |

Driver | Inovance |

Main electrical components | Air tac |

Vacuum pressure sensor | Panasonic, Japan |

7.Software

- American GALIL

- Can be used with production management software

- The cutting head has the function of plunge limit protection, if the cutting head falls outside the glass or the glass gap, the program will automatically stop, effectively preventing damage to parts and glass.

- Capacity calculation function can be performed automatically

- AUTO CAD drawing software is compatible

- The principle axis has an automatic correction compensation function to ensure grooving accuracy

- Operation input: keyboard and mouse. Chinese/English dialogue interface

- It has the function of automatic adjustment of special-shaped glass grooving to ensure the best performance of grooving.

- Automatic matching pressure and speed: according to the pattern, straight line, arc, inner bend, outer bending start, end point; Optimize the cutting path such as acceleration section and deceleration section to adjust the most suitable allowance and speed of output.

- Shaped Gallery: With dozens of shaped galleries, this gallery caters to all possibilities.

- Chinese/ English operation interface

- Drilling positioning function: The pre-positioning function of drilling is available in the shaped gallery.

- Principle axis protection function: with mechanical protection function.

- Shaped glass grooving: The equipment can accurately and automatically groove any straight line, oblique line or shaped.

- Travel protection: The maximum stroke of the equipment has both mechanical and electrical protection.

- Real-time tracking and display of machining path, timely recording of motion coordinates, axis status, etc., fault diagnosis and alarm automatic recording

Key words:

Product Message

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: