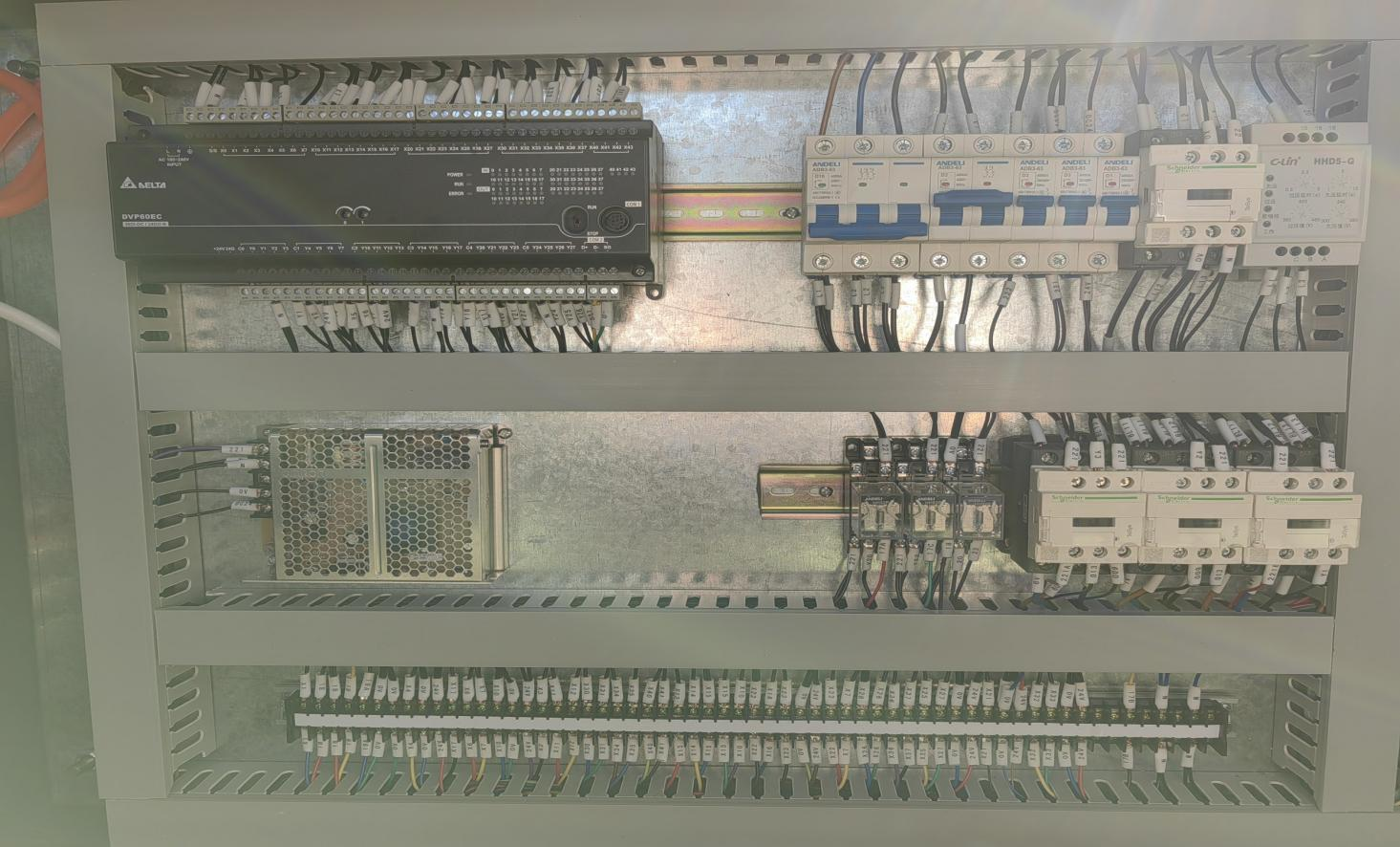

Delta PLC

PRODUCTS SHOW

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp:

+86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

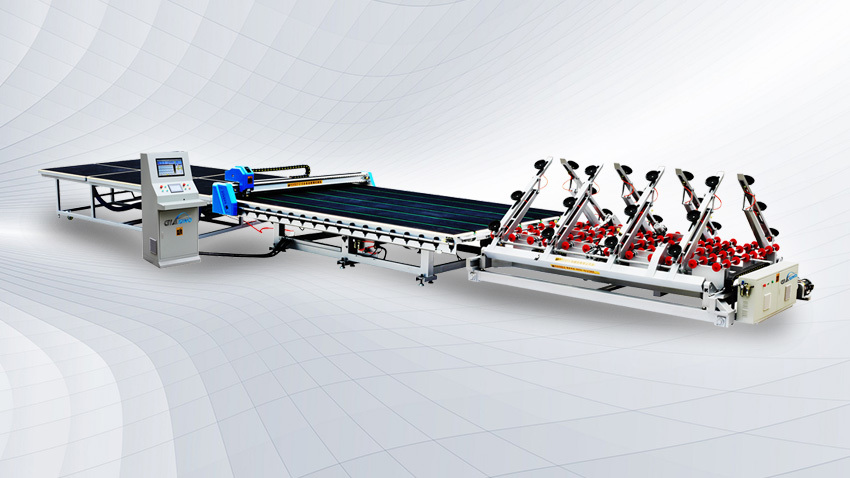

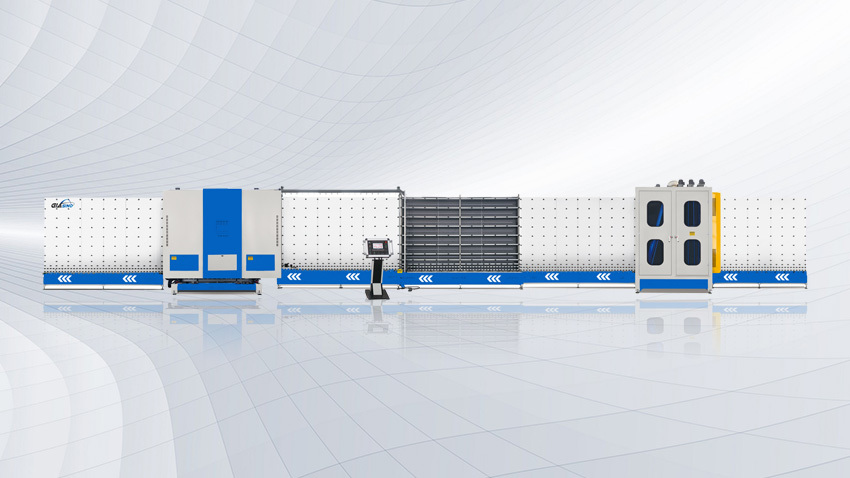

Automatic Glass Loading and Unloading Machine

Category:

Summary:

Tel:

E-mail:

DESCRIPTION

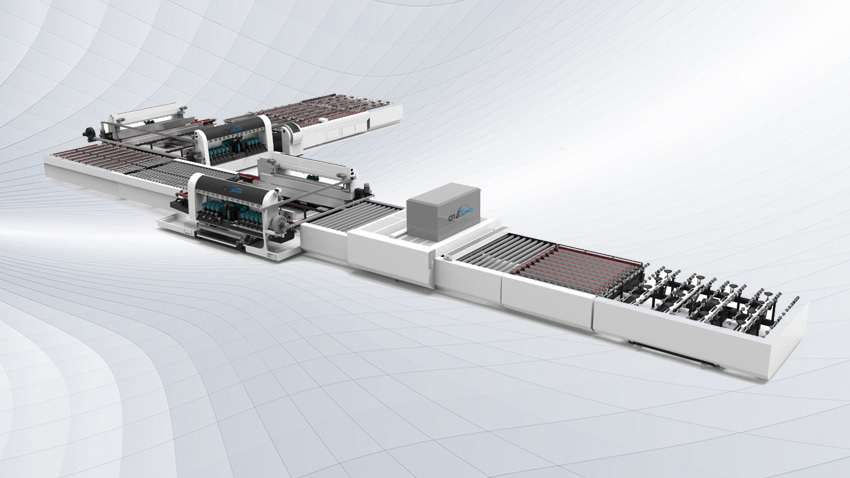

1.GS-QSP-4228 Automatic Glass Loading Machine

Mechanical characteristic:

-Main bridge steel (Q345A ), perfect surface treatment

-High quality vacuum system, fast sucking speed and high stability

-One key original reset function, for improving work efficiency

-Trouble alarm system and safety alarm system

-Four-bar linkage glass lift structure

-High density PU material glass convey wheel

-Acrylonitrile-butadiene rubber suck disc

-40CBM/hour vacuum pump.

-Enclosed wire and air pipe set

Main parts list:

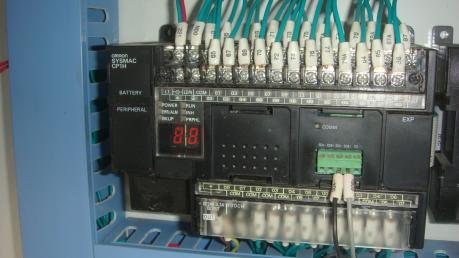

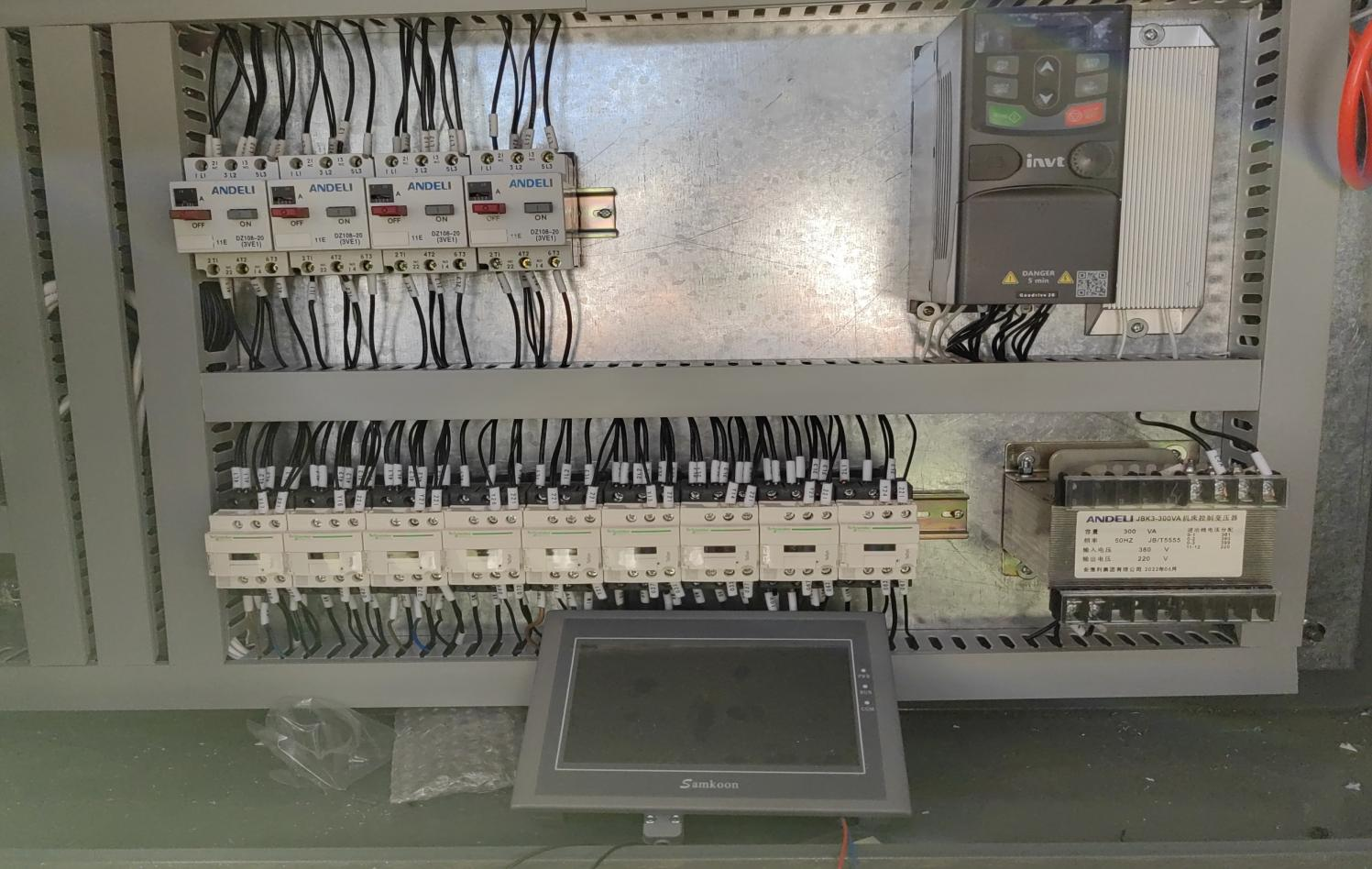

PLC: Delta Taiwan China

Touch screen: MCGS

Converter: Teco (Taiwan)

Sensor: Omron (Japan)

Technical introduction:

-Tilt and suck: tilt angle adjustable, 3-19mm glass sheet auto-suck, suck depth 750mm

-Chain convey after glass suck

-Both auto and manual modes

-Auto alarm system and emergency button for make sure safety operation

-English language touch screen operation

-Glass sheet quantity and station position auto set

-Loading sequence: move-arm tilt up-glass sheet sense-glass sheet vacuum suck-move back-arm tilt flat-glass transmit to cutting table

Technical parameter:

Max loading size | 4200*2800mm |

Loading glass thickness | 3~19mm |

Fastest cycle loading time | 40~50S |

Max loading depth | 700mm |

Max loading weight | 900KG(19mm size 3660/2440) |

Single side(double side) loading bars | 4 arms |

Suckers on each arms | 3 pcs |

Installation power | 8KW |

Air compressor | 0.3Mpa |

Vacuum pressure | -70~90Kpa(adjust by glass thickness) |

More pictures

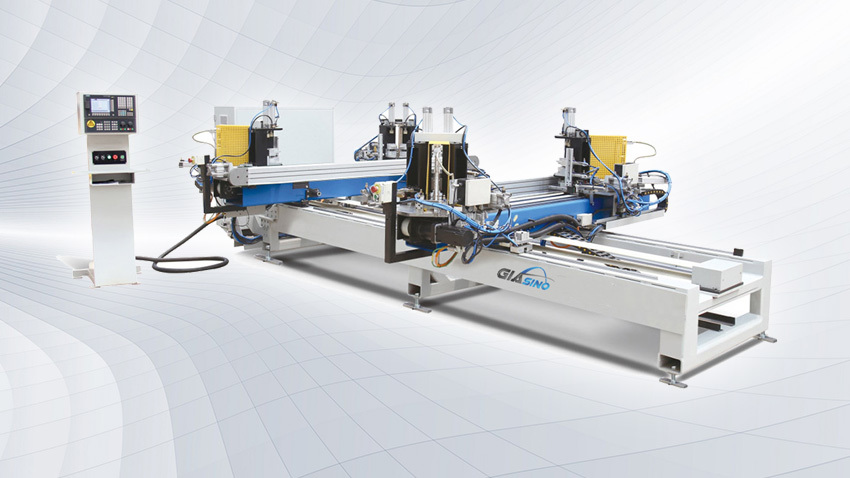

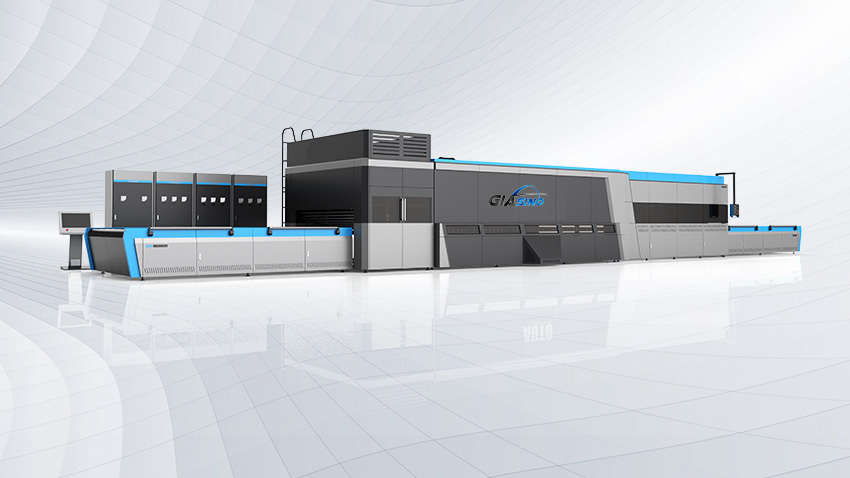

2.GS-QSP-6133 Automatic Glass Loading Machine

Mechanical characteristic:

- Mn bridge steel (Q345A ), perfect surface treatment

- High quality vacuum system, fast sucking speed and high stability

- One key original reset function, for improving work efficiency

- Trouble alarm system and safety alarm system

- Four-bar linkage glass lift structure

- High density PU material glass convey wheel

- Acrylonitrile-butadiene rubber suck disc

- 40CBM/hour vacuum pump

- Enclosed wire and air pipe set

Main parts list:

- PLC: Delta (Taiwan)

- Touch screen: MCGS

- Converter: Teco (Taiwan)

- Sensor: Omron (Japan)

Technical introduction:

- Tilt and suck: tilt angle adjustable, 3-19mm glass sheet auto-suck, suck depth 750mm

- Chain convey after glass suck

- Both auto and manual modes

- Auto alarm system and emergency button for make sure safety operation

- English language touch screen operation

- Glass sheet quantity and station position auto set

- Loading sequence: move-arm tilt up-glass sheet sense-glass sheet vacuum suck-move back-arm tilt flat-glass transmit to cutting table

Technical parameter:

Model | Max. glass size | Thickness | Dimensions (L*W*H) | Power | Air pressure |

QSP-2620 | 2600*2000mm | 2~19mm | 3560*2200*900mm | 8KW | 0.6~0.8MPa |

QSP -4228 | 4200*2800mm | 3~19mm | 5000*2850*900mm | 8KW | 0.6~0.8MPa |

QSP -5133 | 5100*3300mm | 3~19mm | 5400*3000*900mm | 8KW | 0.6~0.8MPa |

QSP -6133 | 6100*3300mm | 3~19mm | 6430*3340*900mm | 8KW | 0.6~0.8MPa |

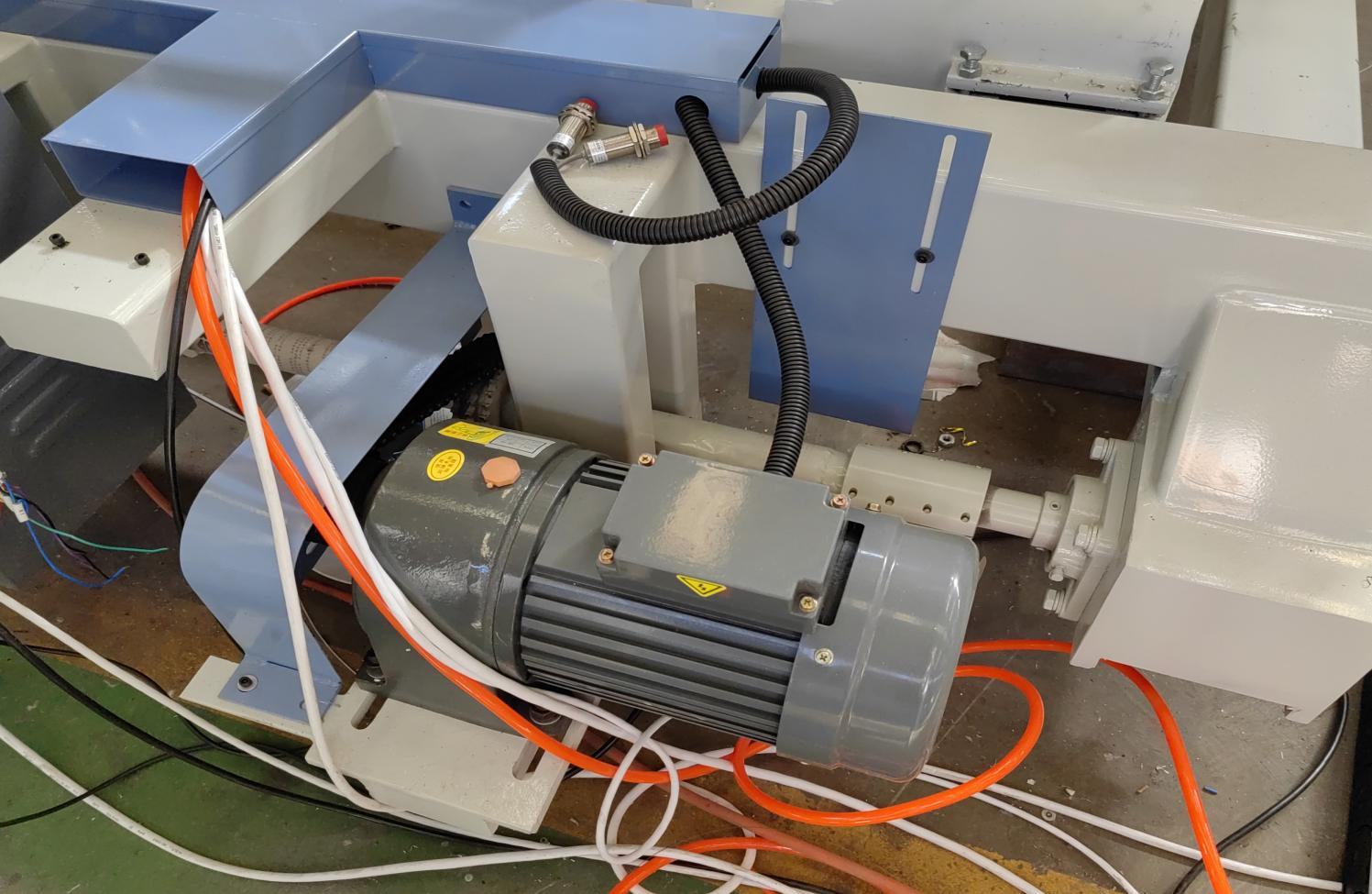

Machine Detail Picture Reference

Key words:

Product Message

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: