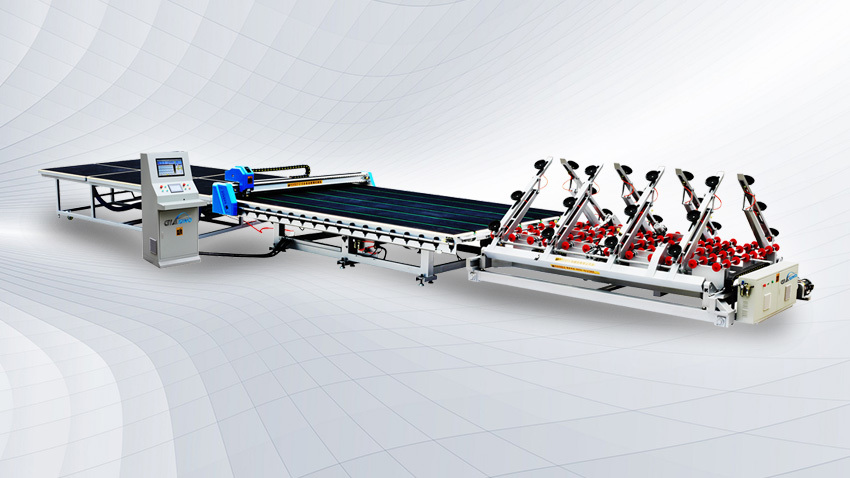

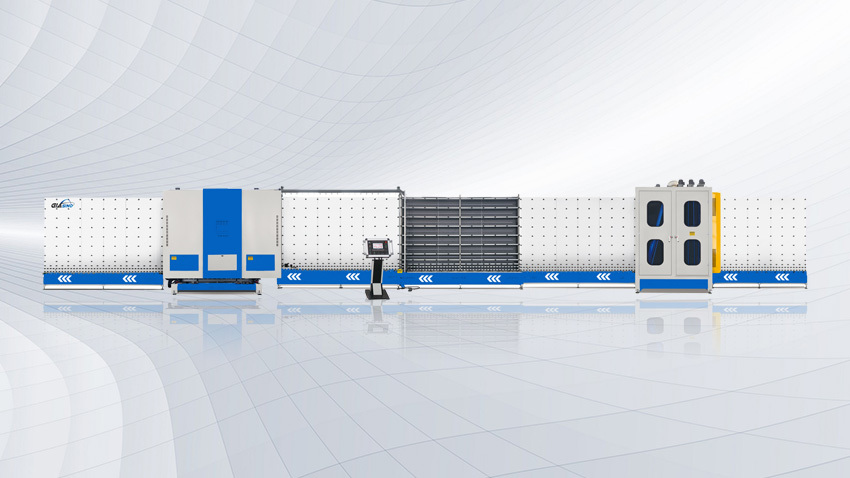

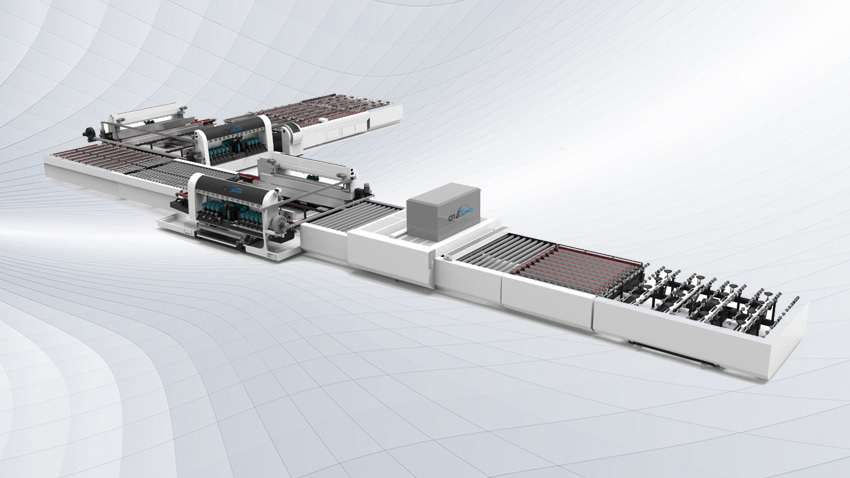

PRODUCTS SHOW

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp:

+86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

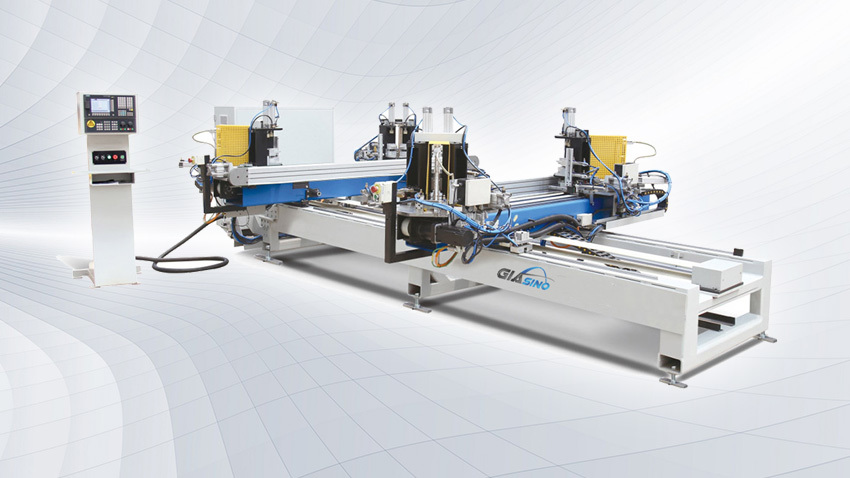

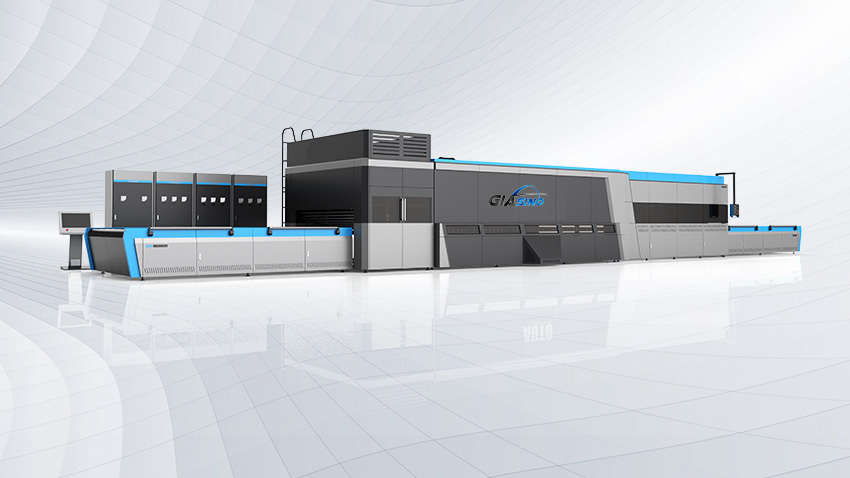

Aluminum Spacer Bending Machine

Category:

Summary:

2.Airtac pneumatic parts

3.Omron servo motor for feeding and bending The Aluminum Spacer Bending Machine is a remarkable piece of equipment that plays a crucial role in the processing of aluminum spacers. This machine is designed to bring precision and efficiency to the bending process of these components.

Tel:

E-mail:

DESCRIPTION

Brief Introduction:

1.Siemens PLC control,Eview touch screen

2.Airtac pneumatic parts

3.Omron servo motor for feeding and bending

4.Error after bending±0.3

5.Four spacer selective storage areas for four kinds of different lengths of spacers

6.The machine will keep away the connect point,arch point during bending and cutting

7.Manual operation is available for easy maintenance

8.Different shapes of alu-spacer bending is available,such as triangle,rectangle,pentagon,hexagon and arch shape

Technical Parameter:

1.Spacer width:6~20mm

2.Minimum spacer frame size:200×250mm

3.Maximum spacer frame size:2500×2500mm

4.Bending speed:less than 30s/frame(1000*1000mm)

5.Air pressure:0.6Mpa

6.Overall dimensions:10000×2100×2600mm(L×W×H)

Features:

1.Rotating arm,easy to operate

2.Bending heads adjustable according to width of aluminum spacer

3.Double stations for improving work efficiency(three or four can do it)

4.Automatic feeding and cutting of aluminum spacer

5.Shape bending a,support continuous bending

6.USB input function,which can read Excel forms directly

7.All stainless steel panels

8.Automatic error compensation function,higher accuracy

9.Code spraying function of aluminum spacer

10.Low-voltage appliances:Schneider,France;

PLC:Germany Siemens;

Air valve:Taiwan AirTac

11.Real-time monitoring of aluminum spacer position

12.Turn the tool head ahead of time to ensure complete cutting

13.Folding stainless steel,SWISS Spacer and other warm edge,aluminum spacer.

|

Name |

Brand |

Remark |

|

PLC |

Siemens |

Germany |

|

Servo Motor |

Omron |

Japan |

|

Relay |

Muller |

Germany |

|

Touch screen |

WEIN-VIEW |

Taiwan |

|

Proximity switch |

Omron |

Japan |

|

Microswitch |

Omron |

Japan |

The Aluminum Spacer Bending Machine is a remarkable piece of equipment that plays a crucial role in the processing of aluminum spacers. This machine is designed to bring precision and efficiency to the bending process of these components.

The Aluminum Spacer Bending Machine is engineered with advanced technology and high-quality materials to ensure reliable and consistent performance. It is capable of accurately bending aluminum spacers to the desired shape and angle, meeting the specific requirements of various applications.

One of the outstanding features of this machine is its ability to handle different sizes and thicknesses of aluminum spacers. Whether it's for small-scale or large-scale projects, it can adapt and provide precise bends. The machine's adjustable settings allow for customization, enabling manufacturers to create spacers with unique geometries.

The bending mechanism of the Aluminum Spacer Bending Machine is highly precise. It ensures that the bends are smooth and uniform, without any distortion or defects. This results in high-quality spacers that fit perfectly in their intended installations, enhancing the overall functionality and aesthetics of the final products.

Efficiency is another key aspect of this machine. It is designed to operate quickly, minimizing the time required for the bending process. This helps to increase productivity and meet tight deadlines in industrial settings. Additionally, the machine is often equipped with automated features and controls that simplify the operation and reduce the chances of errors.

The Aluminum Spacer Bending Machine also offers durability and stability. It is built to withstand the rigors of continuous use and can handle heavy workloads. The components are made to last, ensuring long-term performance and minimizing the need for frequent maintenance or replacements.

In addition to its technical capabilities, this machine is user-friendly. Operators can easily learn and master its functions, thanks to its intuitive interface and clear instructions. Training time is reduced, and workers can quickly become proficient in operating the machine, maximizing its potential.

In the manufacturing industry, the Aluminum Spacer Bending Machine is an essential tool for producing high-quality aluminum spacer components. It allows for greater flexibility and customization in the design and production process. From architectural applications to industrial equipment, these bent spacers play a vital role in providing support, insulation, and other functions.

Furthermore, the machine's precision and efficiency contribute to cost savings. By minimizing waste and ensuring accurate bends, manufacturers can optimize their material usage and reduce production costs. This makes the Aluminum Spacer Bending Machine a valuable investment for businesses looking to improve their bottom line.

In conclusion, the Aluminum Spacer Bending Machine is a sophisticated and indispensable piece of equipment for the processing of aluminum spacers. With its precision, efficiency, durability, and user-friendliness, it empowers manufacturers to create high-quality spacer components that meet the diverse needs of various industries. Its role in enhancing the functionality and performance of products makes it a key asset in the manufacturing process.

Key words:

Product Message

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: