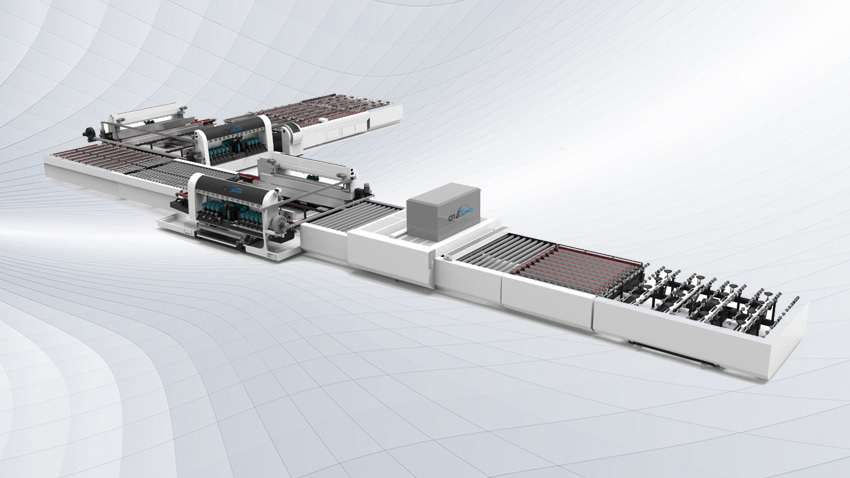

PRODUCTS SHOW

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp:

+86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

Glass Bending Furnace

Category:

Summary:

Tel:

E-mail:

DESCRIPTION

Ⅰ. Main technical target:

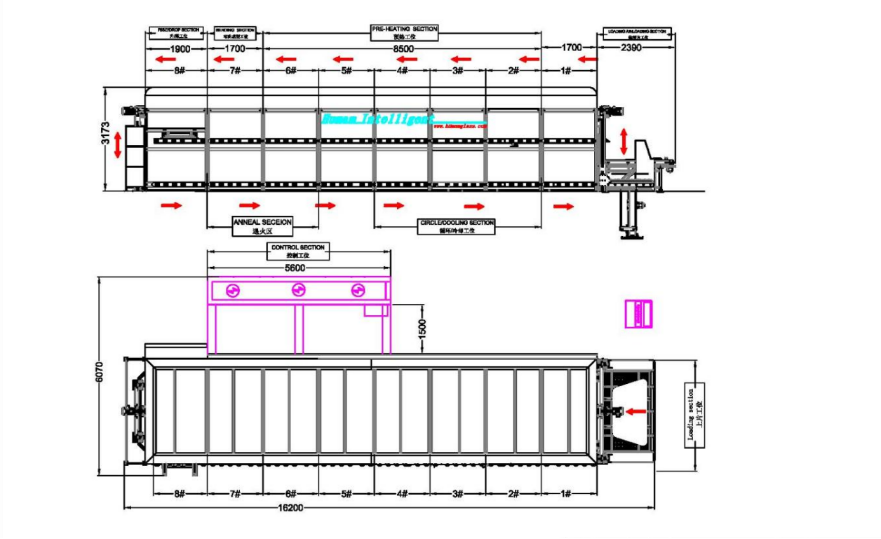

Name | Parameters |

Appearance size (L*W*H) | 16200mm*6070mm*3200mm |

Wagon inner size (L*W*H) | 2500x1600 x400mm |

Weight | About 53000Kg |

Wagon quantity | 15 |

Operating stations | 17 |

Max glass size | 2300*1400mm (Maximum glass size of mold without counterweight and without hinge: 2400*1500mm) |

Glass maximum bending depth | 380mm |

Minimum radius of curvature | 180mm |

Power supply requirements | 380VAC/ 3 P,50HZ |

Installation Power | 1690kw/h (Running power about 70-80%) |

Glass thickness | 2-6mm/pc |

Productivity | 5-10 batches/1h |

Power consumption | 7-9kw/h/m² |

There are observation Windows on both sides of the molding area, and 2 high-temperature cameras are installed.

The finished glass that come out through conveyor belt is still very hot but will not affect and damage conveyor belt quality; The material used for conveyor belt is Teflon which can use in high temperature with smooth surface that will not affect glass quality and will not leave oil on the surface of glass.

II. Technical performance

Product performance: In line with GB-9656(2003) automotive safety glass quality standards; Meet OEM product inspection standards; Comply with GB 9656-2021 Motor vehicle glass safety technology

1. Intelligent operating system:

The operation interface has manual mode and automatic mode.

Manual mode: Click the run button to run the car, and you can detect the working state of the electric heating wire. And routine maintenance, repair work.

In automatic mode, there are hot furnace mode and hot bending mode:

2. Hot furnace mode:

From cold furnace heating to a stable state ready for production. The hot furnace mode can better protect the components of the equipment, so that the furnace reaches a stable hot state from a cold state.

Hot bending mode: Achieve a stable state of production.

Operation interface: Computer operation using Windows Dynamic Picture, easy for Human-Machine interactive dialogue;

The bending furnace operation and settings are performed by control panel (keyboard and monitor);

Manually setting and storing glass bending parameters in the first production, all the technical parameters can be amended during production and it can be saved or not;

Glass types can be reach up to 4000 kinds;

Storage the bending parameter will set operation limit of authority, while deleting the bending parameter has to input password by prescriptive operator.

Installing the Infinite point easy operation control software infinite point easy operation control software.

When the furnace get malfunction, there will be alarm and record and it can check the root of fault then easy for debugging.

Equipment design has its own mechanical limit protection function.

The action pattern can run with automatic and manual mode;

Heating has preheating and bending mode;

Equipment control with automatic and manual mode;

There is testing function used for heating elements working is normal or not; Install high-performance watt-hour meter, connect with computer and record electricity power consumption.

3. There is a mold positioning mechanism inside the cart, which can quickly place the mold in the center of the wagon and fix the mold at the same time. The surface of the thermal insulation cotton is poured with high temperature coating to synthesize high temperature water. After heating, the surface of the thermal insulation cotton is hardened to play the role of thermal insulation and resist external force.

4.Secondary forming mechanism (glass bending auxiliary pushing rod mechanism) : the use of glass with deep curvature on both sides (glass bending auxiliary pushing rod mechanism) : for the glass with large curvature, the auxiliary structure is added to the mold, and the hot bending is carried out according to the preset formula, and the mold auxiliary pushing rod mechanism is automatically propelled to push off the mold auxiliary mechanism, and the glass pre-bending process is completed. Two forming driving mechanism, to achieve two forming of large spherical products, improve the optical problems of large spherical products.

Key words:

Product Message

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: