NEWS CENTER

16

2025

-

09

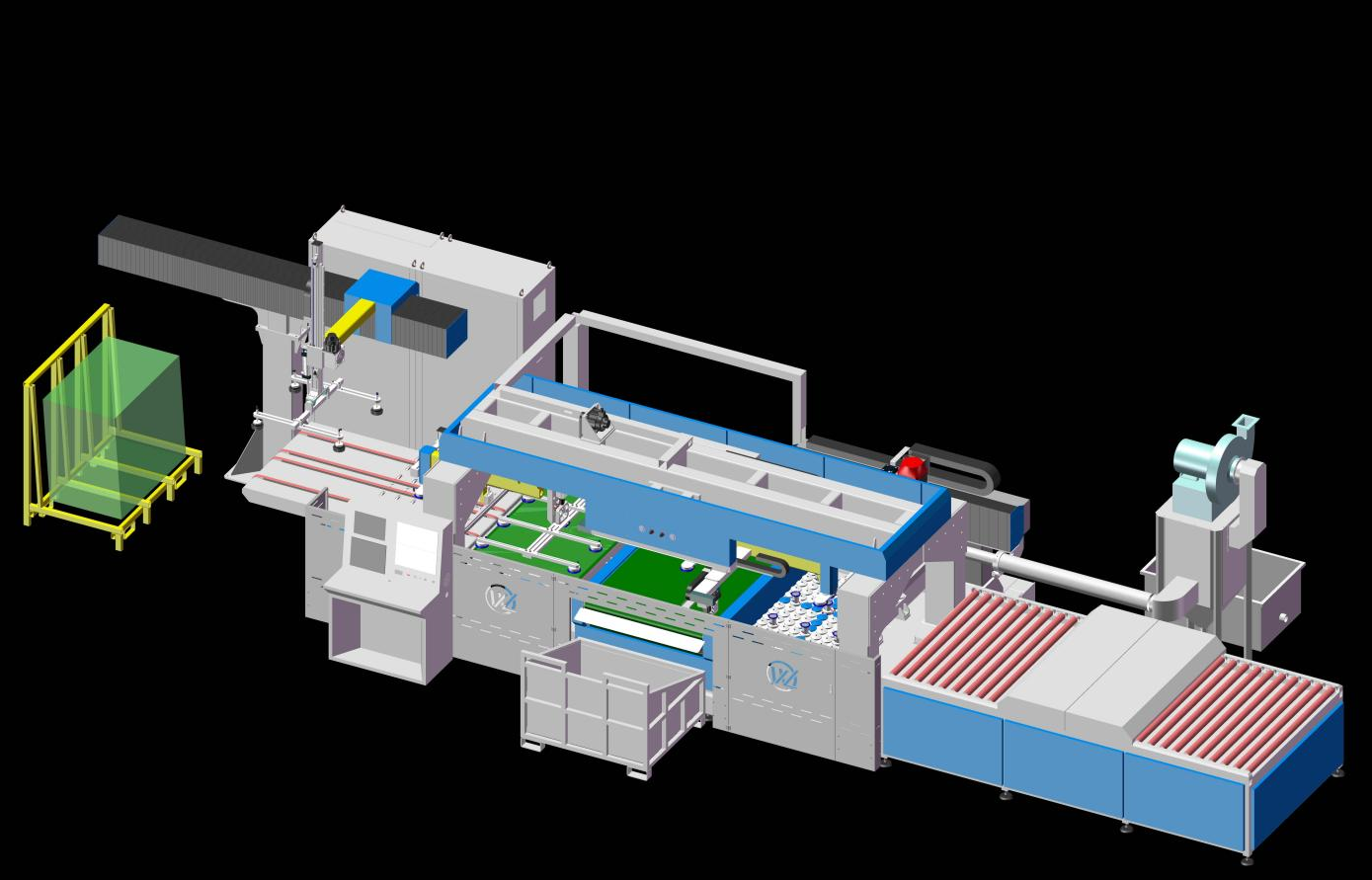

TPS Insulating Glass Production Line

The TPS Insulating Glass Production Line is a fully automated production line designed for high-end windows, doors, curtain walls, and energy-efficient buildings. It is specifically designed to produce next-generation insulating glass (IG) using thermoplastic spacers (TPS). Compared to traditional aluminum or stainless steel insulating glass processes, the TPS line offers significant advantages in efficiency, energy consumption, and product performance.

The line utilizes an intelligent control system that automates the entire process, including glass cleaning, positioning, spacer coating, assembly, lamination, and airtightness testing, significantly improving production efficiency. TPS thermoplastic spacer material offers excellent sealing and thermal conductivity, resulting in insulating glass with lower thermal conductivity, effectively improving building energy efficiency and meeting passive building and green energy standards.

Designed with flexibility in mind, the TPS Insulating Glass Production Line is compatible with a variety of glass specifications and thicknesses, making it suitable for processing double-layer, triple-layer, and oversized IG units. The automated TPS extrusion and coating system ensures uniform adhesion of the spacers to the glass edges, ensuring the aesthetics and stability of the finished product. Compared to traditional processes, the TPS insulating glass production line eliminates the need for cutting, bending, and loading molecular sieves, reducing manual labor and material waste, making the production process more streamlined and efficient.

In addition, the TPS insulating glass production line features highly intelligent detection capabilities. Through its integrated online quality monitoring system, the equipment monitors spacer thickness, glass positioning accuracy, and seal integrity in real time, effectively reducing defective product rates. Its advanced human-machine interface (HMI) operating system allows operators to easily set process parameters and monitor the production process, significantly enhancing operational convenience.

In terms of energy conservation and environmental protection, the production line optimizes its heating and transmission systems to reduce energy consumption and extend equipment life. TPS insulating glass, lacking the cold bridge effect of metal frames, offers superior performance and a longer service life. It is widely used in high-end buildings, energy-saving doors and windows, and locations requiring high thermal and sound insulation.

The TPS Insulating Glass Production Line not only represents the trend toward automation and intelligent development in insulating glass production equipment, but also, with its advantages of high efficiency, precision, and energy saving, it brings greater market competitiveness and substantial economic benefits to glass processing companies.

TPS Insulating Glass Production Line

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: