NEWS CENTER

06

2024

-

09

Several pieces of equipment began to be packed and shipped to Macedonia!!!

Several pieces of equipment began to be packed and shipped to Macedonia!!!

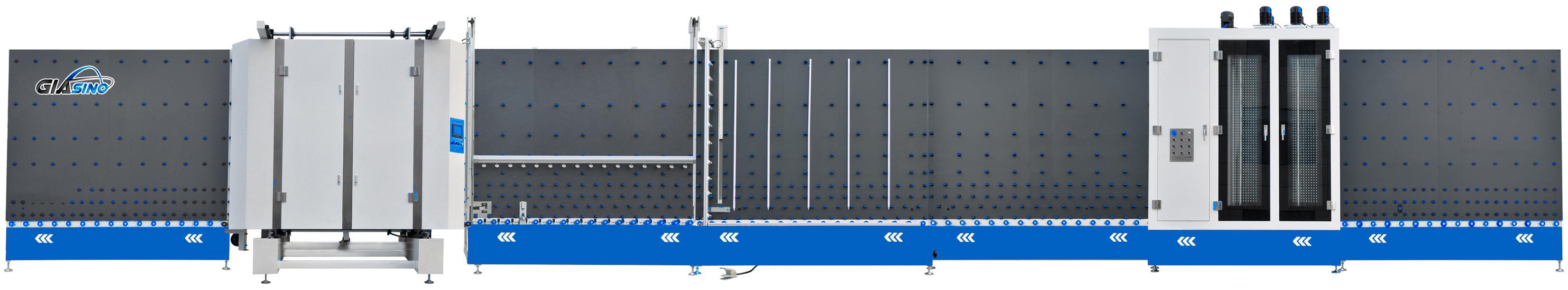

1.Automatic Insulating Glass Production Line

Equipment Features: 1. PLC control touch screen human-machine interface. 2. Automatic identification of coated glass and LOW-E glass film layer. 3. The application of imported vacuum generator and suction cup make better glass catching effect. 4. Three pairs of glass cleaning hairbrushes rotation speed can be driven by frequency conversation. 5. Big small sized and three layer hallow glass can be produced according to customer requirements. 6. Digital controlled assembling line to save production time and improve efficiency. 7. The production panel has been processed with plastic spraying to achieve beautiful appearance and durable service life. 8. Cleaning machine is made with stainless steel and resistance material. 9. All electric appliance are selected from famous international brand. 10. The press section can be pushed to 450mm with big stroke to make it convenience for maintenance. (Optional) 11. When for exterior conjunction the plate press adopts central location way. 12. Free alternative between interior and exterior cunjunction. 13. The press section adopts opening-door style to convenient overhaul and maintenance.

2.Butyl Sealant Coating Machine

Product Feature:

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: