NEWS CENTER

13

2024

-

11

automatic glass cutting machine

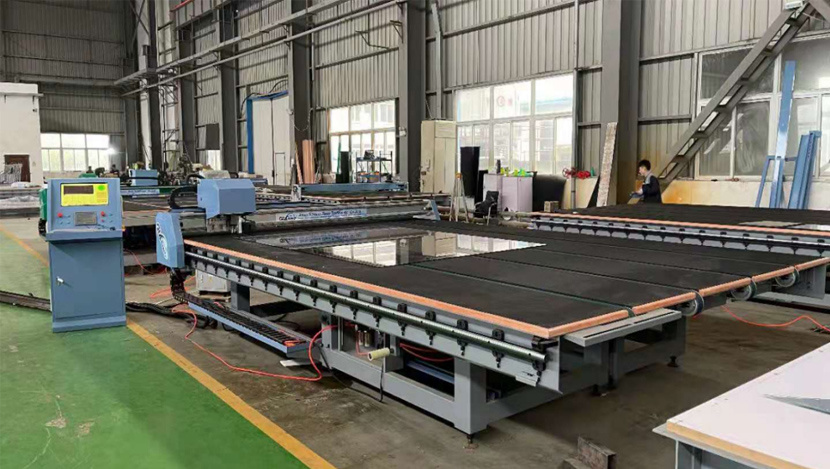

Glasino CNC automatic glass cutting line is composed of auto glass loading machine,CNC glass cutting machine and air float glass breaking table,which can realize glass automatic loading,transmission,positioning,optimization,cutting and breaking function.

The three machines are controlled by one central controller,and compose an automatic glass cutting line in high efficiency and precision.

The glass cutting line mainly contains three sections:

1.Automatic Glass Loading Machine

2.Automatic Shaped Glass Cutting Machine

3.Glass Breaking Table

Technical parameter:

Model | Max. glass size | Thickness | Dimensions (L*W*H) | Max. speed | Air pressure |

CNC-4228 | 4200*2800mm | 3~19mm | 14500*3600*1300mm | 180m/min | 0.6~0.8MPa |

CNC-2620 | 2600*2000mm | 2~19mm | 11000*3000*1300mm | 150m/min | 0.6~0.8MPa |

CNC-5133 | 5100*3300mm | 3~19mm | 17000*4212*1300mm | 180m/min | 0.6~0.8MPa |

CNC-6133 | 6100*3300mm | 3~19mm | 19980*4212*1300mm | 180m/min | 0.6~0.8MPa |

CNC-8533 | 8500*3300mm | 3~19mm | 27000*4200*900mm | 180m/min | 0.6~0.8MPa |

CNC-10033 | 10000*3300mm | 3~19mm | 32000*4200*900mm | 180m/min | 0.6~0.8MPa |

Glass loading Machine:

| Max loading size | 4200*2800mm |

| Loading glass thickness | 3~19mm |

| Fastest cycle loading time | 40~50S |

| Max loading depth | 700mm |

| Max loading weight | 900KG |

| Single side(double side) loading bars | 4 arms |

| Suckers on each arms | 3 pcs |

| Installation power | 8KW |

| Air compressor | 0.3Mpa |

| Vacuum pressure | -70~90Kpa(adjust by glass thickness) |

| PLC | Taiwan Delta |

Glass cutting Machine:

| Max cutting glass layout | 4200*2800mm |

| Working table height | 900±50mm |

| Glass thickness | 3~19mm |

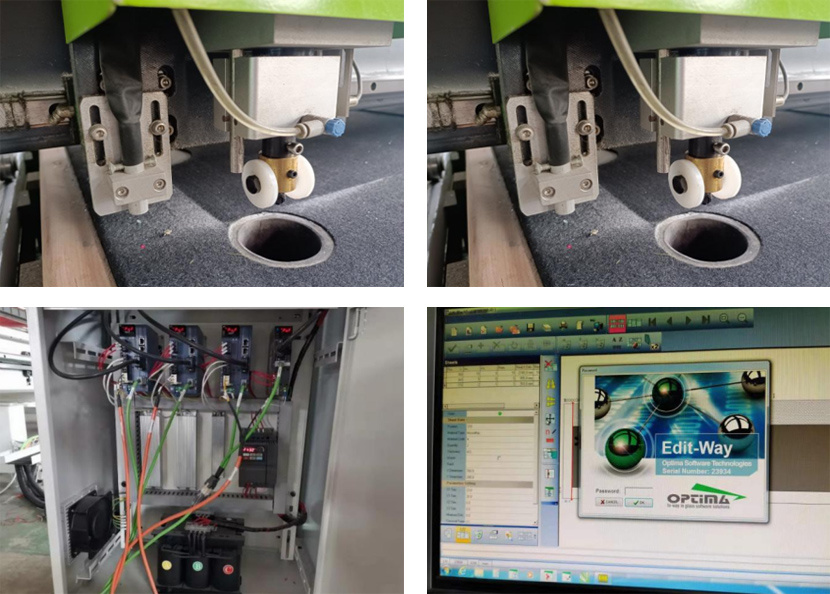

| Servo Motor and Drives | Japan Yaskawa |

| Control Board | USA Galil |

| Cutting Software | China Powerland |

| optimization software | Italy Optima |

| Linear parallel | ≤±0.20mm/m |

| Diagonal accuracy | ≤±0.25mm/m(The above accuracy is base on glass before breaking) |

| Cutting bridge speed | 0~280m/min(can be adjusted) |

| Cutting bridge acceleration | ≥3.0m/s2 |

| Cutting head speed | ≥150m/min |

| Cutting head acceleration | ≥6.0m/s2 |

| Cutting head positioning accuracy error | ≤±0.15mm |

| Machine total power | 8KW |

| Air compressor | 0.6MPA |

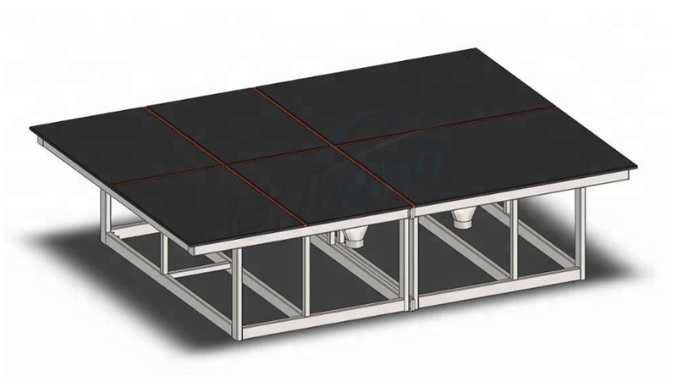

Glass breaking Table: 4200*2800mm:

| Max. glass size | 4200*2800mm |

| Breaking bars | 1+2 |

| Air float function, MDF board | |

| Power | 6.6kw |

| Multi point push rod control function, convenient and reliable | |

Details

The automatic glass cutting machine is a remarkable technological innovation that brings precision and efficiency to the glass processing industry.

This machine is engineered to handle the complex task of cutting glass with remarkable accuracy and speed. It utilizes advanced sensors and intelligent control systems to ensure exact cuts, minimizing waste and maximizing productivity.

The automatic glass cutting machine offers a seamless and automated process. Once the parameters are set, it operates with minimal human intervention, allowing for continuous and consistent production. It can handle various glass thicknesses and types, making it highly versatile.

With its high-precision cutting blades and adjustable settings, it creates clean and smooth cuts, meeting the stringent requirements of different applications. Whether for architectural glass, automotive glass, or other industries, this machine delivers outstanding quality.

The user interface of the automatic glass cutting machine is designed to be intuitive and easy to operate. Operators can easily program and monitor the cutting process, ensuring optimal performance and quick adjustments as needed.

In addition to its cutting capabilities, some models may also offer additional features such as marking, drilling, or shaping of the glass. This enhances its functionality and provides added value to users.

The durability and reliability of the automatic glass cutting machine are also key factors. Built with robust materials and components, it is capable of withstanding heavy usage in industrial environments. Regular maintenance is relatively straightforward, ensuring the machine remains in top condition for a long time.

Safety is a top priority, and the machine is equipped with safety mechanisms to protect operators from potential hazards. It provides a secure working environment while allowing for efficient glass cutting operations.

Overall, the automatic glass cutting machine is a game-changer in the glass manufacturing and processing sector. Its ability to deliver precise cuts, high efficiency, and user-friendly operation makes it an essential tool for businesses looking to stay ahead in a competitive market. It simplifies the glass cutting process, saves time and resources, and enables the creation of high-quality glass products with ease.

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: