NEWS CENTER

23

2025

-

05

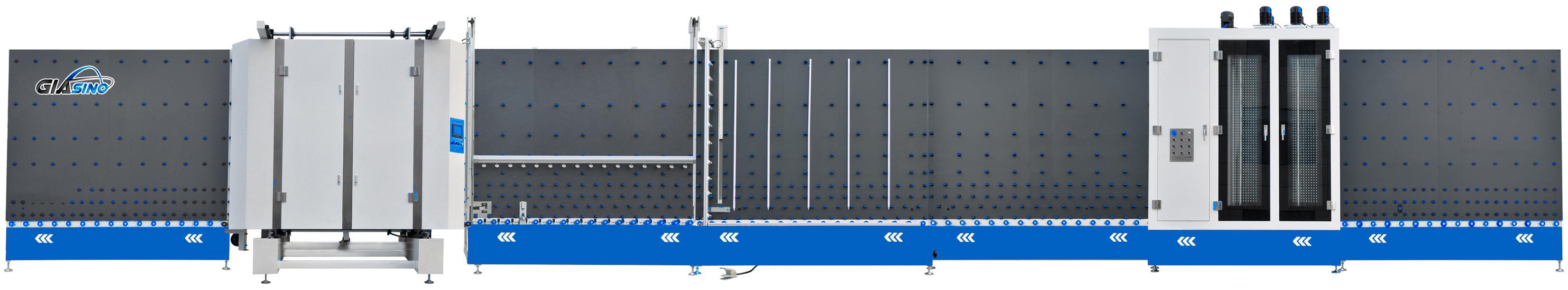

Insulating Glass Machine: Advanced Solutions for Energy-Efficient Window Production

The growing demand for energy-saving buildings has made the insulating glass machine a cornerstone of modern fenestration manufacturing. These sophisticated systems automate the production of double or triple-pane insulating glass units (IGUs), combining precision engineering with cutting-edge technology to create high-performance windows.

A state-of-the-art insulating glass machine typically integrates multiple processes into one streamlined system. From glass washing and spacer application to butyl sealing and gas filling, these machines ensure perfect alignment and airtight seals for optimal thermal insulation. The latest insulating glass machine models feature intelligent sensors and computerized controls that maintain consistent quality across production batches.

Efficiency is a hallmark of modern insulating glass machine technology. Automated material handling reduces labor requirements while minimizing errors in spacer placement and sealant application. Many manufacturers now offer insulating glass machine configurations that can process different glass thicknesses and spacer types, providing flexibility for custom IGU production.

Durability and low maintenance make the insulating glass machine a smart long-term investment for window fabricators. With proper calibration, these systems can operate continuously while maintaining precise tolerances for years. As energy codes become stricter worldwide, the role of the insulating glass machine in sustainable construction continues to grow in importance.

insulating glass machine

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: