NEWS CENTER

11

2025

-

06

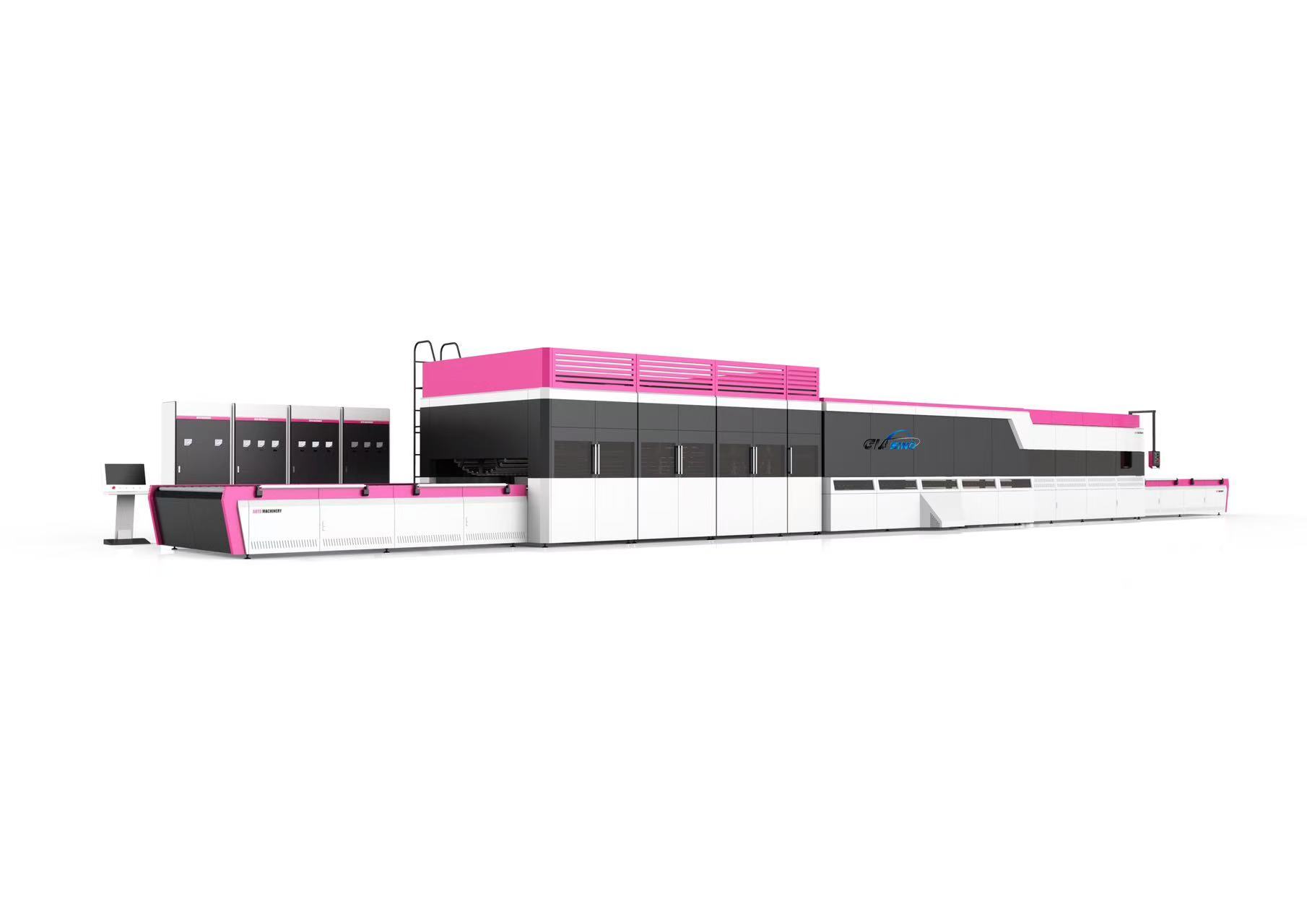

China Glass Tempering Furnace: The Heart of Safety Glass Production

The glass tempering furnace represents the core technology behind all modern tempered safety glass manufacturing. As an essential piece of equipment in glass processing plants worldwide, a high-performance glass tempering furnace transforms ordinary float glass into safety-rated tempered glass through precisely controlled thermal treatment.

Modern glass tempering furnaces feature advanced convection heating systems that ensure uniform temperature distribution across the entire glass surface. The latest generation glass tempering furnace incorporates intelligent control systems that automatically adjust heating parameters based on glass thickness, type, and desired stress levels. What sets apart premium glass tempering furnaces is their ability to maintain temperature consistency within ±1°C throughout the entire heating chamber.

Key advantages of investing in a professional-grade glass tempering furnace include:

1. Energy-efficient ceramic heating elements that reduce power consumption

2. Durable stainless steel construction for long service life

3. Precision quenching systems that create optimal surface compression

4. Automated production capabilities for continuous operation

For glass processors requiring consistent quality and high output, the glass tempering furnace remains an indispensable investment. Whether producing architectural glass, automotive windows, or specialty applications, today's advanced glass tempering furnaces deliver the reliability and performance demanded by global safety standards.

Upgrade your production line with a state-of-the-art glass tempering furnace and elevate your tempered glass quality to industry-leading standards. The right glass tempering furnace not only improves product quality but also enhances overall production efficiency and profitability.

glass tempering furnace

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: