NEWS CENTER

14

2025

-

05

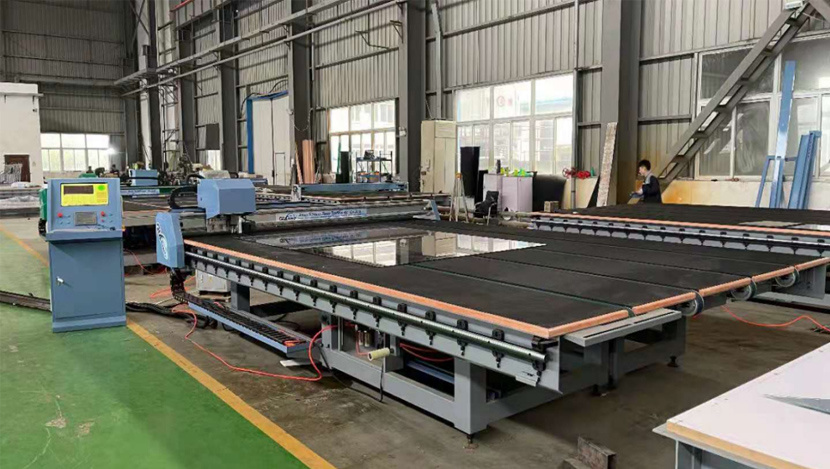

Unlock Precision and Flexibility with a Customized Glass Cutting Machine

In today’s competitive glass industry, a customized glass cutting machine is a game-changer for businesses seeking tailored solutions. Unlike standard models, a customized glass cutting machine is designed to meet specific production requirements, ensuring optimal efficiency and precision for unique applications.

One of the key advantages of a customized glass cutting machine is its adaptability. Whether you need specialized cutting patterns, varying thickness capabilities, or integration with automation systems, a bespoke machine can be engineered to fit your exact needs. This flexibility makes it ideal for industries like automotive, architecture, and electronics.

Another benefit is enhanced productivity. A customized glass cutting machine can streamline workflows by incorporating advanced features such as laser guidance, CNC controls, or automated loading systems. These upgrades minimize errors and maximize output, giving businesses a competitive edge.

Cost efficiency is also a major factor. While off-the-shelf machines may require compromises, a customized glass cutting machine eliminates unnecessary features while focusing on what matters most for your operation. This targeted approach reduces waste and improves ROI.

In conclusion, investing in a customized glass cutting machine ensures superior performance, adaptability, and long-term value. For businesses looking to optimize their glass processing, customization is the key to success.

customized glass cutting machine

Glasino aim: Design and produce new and practical machines, following the development of the glass and window industry.

Product Category

Contact Us

Shandong Glasino Machinery Co.,Ltd.

Address: Building A-610 Mingliu Square, Changqing District Jinan City, Shandong, China

Tel: +86-531-87221996

WhatsApp: +86-15905314037

Email: sales@glasino.cn

Website: www.glasino.cn

E-mail: